THANK YOU FOR SUBSCRIBING

Applied Technology Review: Specials Magazine

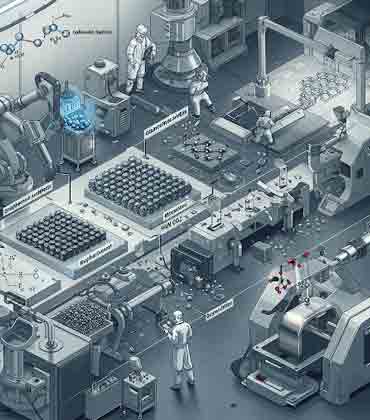

Shinegoal Materials is the world’s first company to bring grapheme-copper (Gr/Cu) to large-scale commercial production—breaking through a performance ceiling that has held back industrial innovation for over a century. Why This Matters? Copper’s conductivity has long been capped at 100 percent by the International Annealed Copper Standard (IACS), limiting progress in electronics, power transmission, telecommunications and high-frequency applications. Silver conducts better, but its high cost and limited supply make it unsuitable for widespread industrial use. Gr/Cu changes that. With 105 percent IACS conductivity, it outperforms traditional copper while remaining far more cost-effective than silver. Its thermal conductivity of 480 W/mK improves heat dissipation, making it ideal for power electronics, 5G infrastructure and EV batteries. In high-frequency environments—where signal integrity is critical—Gr/Cu’s AC resistance is 60 percent lower than oxygen-free copper, reducing energy loss and boosting efficiency. Available in three optimized forms—wire, foil and powder—Gr/Cu is engineered to meet specific needs across advanced industrial sectors. Shinegoal has made next-generation performance a practical reality by overcoming the long-standing barrier of scalable production. “What we have created here is a material that challenges the limits of traditional conductivity and heat management. Graphene-copper can unlock new possibilities for industries that demand higher efficiency, durability and performance,” says Dr. Qiong Wu, CEO. High Performance without The Trade-Offs Graphene’s ability to enhance conductivity and thermal performance is well known, but its industrial use has long been limited by manufacturing challenges. Traditional methods like Chemical Vapor Deposition (CVD) operate at temperatures above 1000°C and use methane—an explosive gas—as a carbon source. These methods are energy-intensive, hazardous and unsuitable for scaling.

Sensor Technology in APAC 2025

Autonics began its journey in 1977 in South Korea, driven by a vision to make industrial automation smarter and more accessible. Over the years, that vision expanded across borders, and the company steadily grew into a trusted name in automation, now present in over 100 countries through a strong network of distributors and subsidiaries. As industries advanced and production demands became more complex, Autonics responded by developing technologies that brought greater precision, efficiency and flexibility to the factory floor. The company’s equipment has helped businesses build more responsive operations, giving them the tools to stay competitive in an environment where every second and every detail matter. A big part of that progress comes from Autonics’ ongoing commitment to research and development. Instead of simply keeping up with change, the company works to stay ahead of it. That mindset is reflected in a wide product lineup that includes sensors, controllers, motion devices, and human-machine interfaces—each designed to integrate seamlessly into manufacturing processes and support continuous improvement. Smart Technologies, Simple Integration Autonics is making waves with its range of automation products that work in synergy to solve industrial challenges. Its sensors are the backbone of many manufacturing systems, providing accurate detection, measurement and monitoring. These sensors allow for precise control, ramping up productivity, and keeping things running smoothly. Add in temperature controllers, timers, counters and panel meters, and it is all about maintaining peak performance and consistent quality. Motion control is another key area in which Autonics excels. The company develops and supplies stepper motors, drivers, and motion controllers that allow for high-speed, high-precision control of mechanical systems. These components are integral to automated machinery that requires reliable and repeatable motion, such as assembly lines and robotic applications. To top it off, Autonics’ human-machine interfaces simplify operator interaction, making it easier to monitor processes, troubleshoot, and improve overall transparency in operations.

MEMS Sensor Solution in APAC 2025

NEW COSMOS ELECTRIC CO., LTD.

Safeguarding the World, One Sensor Ahead

Yoshinori Takahashi, President

This vision led to the creation of New Cosmos Electric Co., Ltd., which has since grown into a global leader in gas detection technology. In 1964, the company introduced the world’s first residential gas alarm and has continued to develop cutting-edge sensor technologies, consistently emphasizing safety, innovation and reliability. Under the leadership of President and CEO Yoshinori Takahashi, New Cosmos Electric has diversified its offerings with innovative products such as residential gas alarms, portable gas detectors and air quality monitors—all of which play a vital role in safeguarding homes, workplaces, and public spaces worldwide. “Our unwavering mission to eliminate gas accidents globally drives our innovations in safety equipment, ensuring we remain at the forefront of gas detection technology,” says Takahashi. Developing micro-electro mechanical systems (MEMS) technology demonstrates the company’s commitment to innovation. This has created more compact, cost-effective, and efficient gas sensors, critical to New Cosmos Electric’s product designs. These advancements have been instrumental in introducing battery-powered natural gas alarms, which enhance safety in residential environments. In addition, smart gas detectors, integrated with Bluetooth capabilities and cloud-based systems for live monitoring, align with modern trends in IoT for smart cities and industrial applications. GLOBAL PRESENCE AND IMPACT New Cosmos Electric, with a workforce of 500–1,000 employees, has expanded its operations worldwide. The company maintains a strong presence in several key regions, including the United States, where it has been serving major utility companies with advanced gas detection solutions since 2018.

CXO INSIGHTS

Using Digital Twins to Reduce Carbon Emissions in the Manufacturing Industry: The Identification of Non-productive Emissions

Dr Michael Lees, Control & Automation Manager, Carlton & United Breweries

New Nanotechnology Trend in the Healthcare and Cosmetic Industry

Jun Sasai, Vice President, Basic and Fundamental Research Dpt. Beauty Innovation Center, Finetoday Co., Ltd

Drone Application in Construction Industry

Henry Chan, Deputy Construction Manager, Dragages Hong Kong Limited

Agentic AI: Unlocking the Future of Business Operations

Athikom Kanchanavibhu, Executive Vice President, Digital & Technology Transformation, Mitr Phol Group

A Vision For The Future: Automation, Robotics, And The Smart Factory

Joe Tilli, State Industrial Automation Sales Manager, Lawrence & Hanson

Mastering Digital Change And Driving Revenue Through Innovation

Nazih Battal, Chief Information & Technology Officer, Rashays

How AI Agents Can Supercharge Decision-Making in Construction

Christian Pallaria, Corporate Computational Design Manager & Sydney Mudau, Project and Program Aviation Sector Lead, Aecom [Nyse: Acm]

Turning Data into Actionable Business Impact with AI and Machine Learning

Agus Jamaludin, Deputy Data Science Manager, Petrosea

Driving Lean Excellence in Advanced Manufacturing

Matt Goodwins, Engineering Manager For Manufacturing And Materials Engineering, Bae Systems Australia

IN FOCUS

Hybrid Composites with Graphene for Future Technologies in APAC

The Asia-Pacific (APAC) region is rapidly emerging as a global hub for advanced materials research and development, with a significant focus on graphene and its integration into hybrid composites.

EDITORIAL

China’s Strategic Bet on the Future of Materials Science

China’s approach is methodical and forward-looking. It recognizes that combining graphene with metals such as copper, aluminum, or titanium could unlock new aerospace, electronics, and energy capabilities. Unlike conventional metals, graphene-infused alloys offer superior conductivity, corrosion resistance, and tensile strength. This makes them ideal for lightweight aircraft components, high-performance batteries, and more resilient electronic devices.

What sets China apart is its capacity to produce these materials and its vision to integrate them into national industrial growth strategies. With state-backed research and deep collaborations between academia and manufacturing sectors, China is building an ecosystem where breakthroughs scale. The country’s material science ambitions are aligned with its broader goals of technological sovereignty and leadership in green innovation.

However, the implications stretch beyond industrial strategy. As other nations grapple with supply chain vulnerabilities and the urgent need for next-generation infrastructure, China’s early investment in graphene-metal alloys could give it a unique edge. Mastering not just the science but the scalable production of these composites secures a foothold in a sector where materials define the limits of innovation.

The stakes are high in the global contest for scientific leadership. In the world of graphene-metal alloys, China is not just participating; it is laying the groundwork to lead.

In this edition, we explore how China is helping businesses leverage graphene-metal alloys to stay ahead of the curve. The magazine features companies like Shinegoal Materials, a company redefining conductivity with its breakthrough graphene-copper alloy. We also present insights from expert CXOs like Frederick Chen, Sr. Technology Manager - Advanced Technology Development, Winbond and David Hermann, ANZ Electrical, Instrumentation and Process Automation Manager, Goodman Fielder, offering their opinions on the currently used business practices. We hope these valuable insights from industry leaders and solutions and services from firms featured in this edition will assist you in making informed decisions for your businesses.

Let us know your thoughts.